|

Lug Nut/Bolt Torque |

Lug Nut/Bolt Type |

**Lug Nut/Bolt Size |

Lug Nut/Bolt Socket Size |

|

130 ft-lb (176 N·m) |

Cone |

M14 x 1.50 |

22 mm |

|

129 ft-lb (175 N·m) |

Flanged |

**Use only authorized dealer recommended lug nuts/bolts and clean or remove any dirt or oil before tightening.

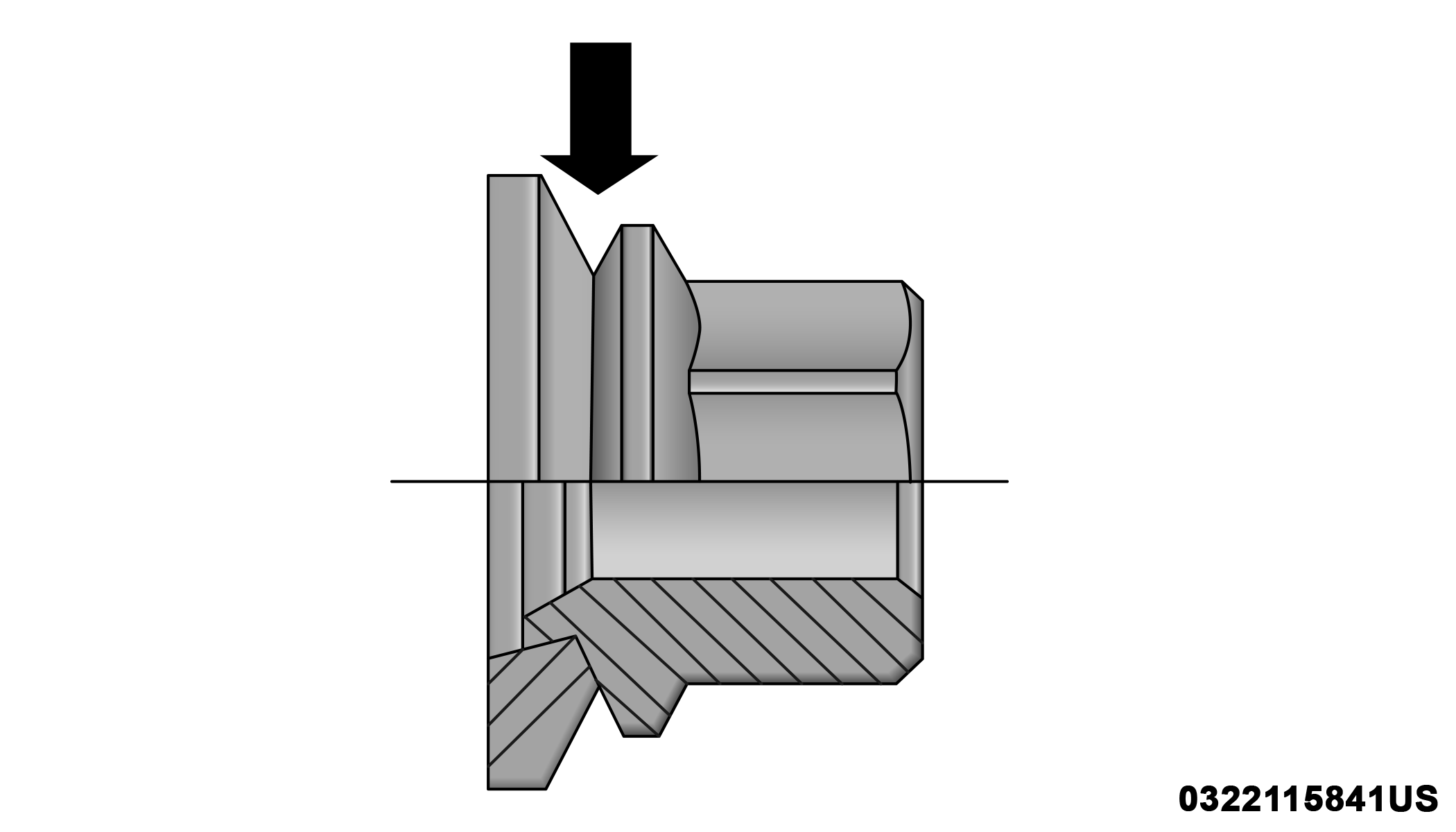

Two-Piece Lug Nut

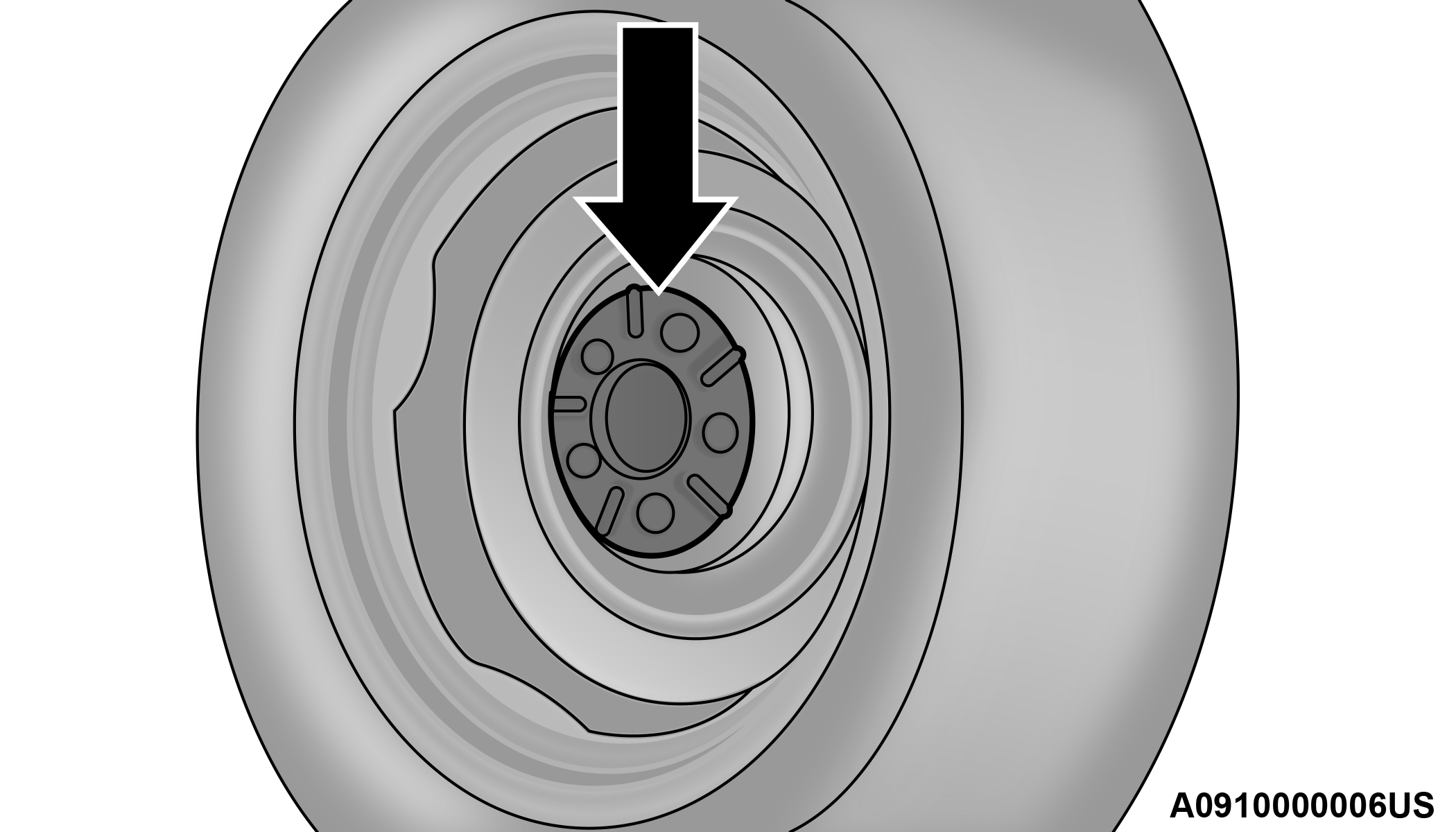

Inspect the wheel mounting surface prior to mounting the tire and remove any corrosion or loose particles.

Wheel Mounting Surface

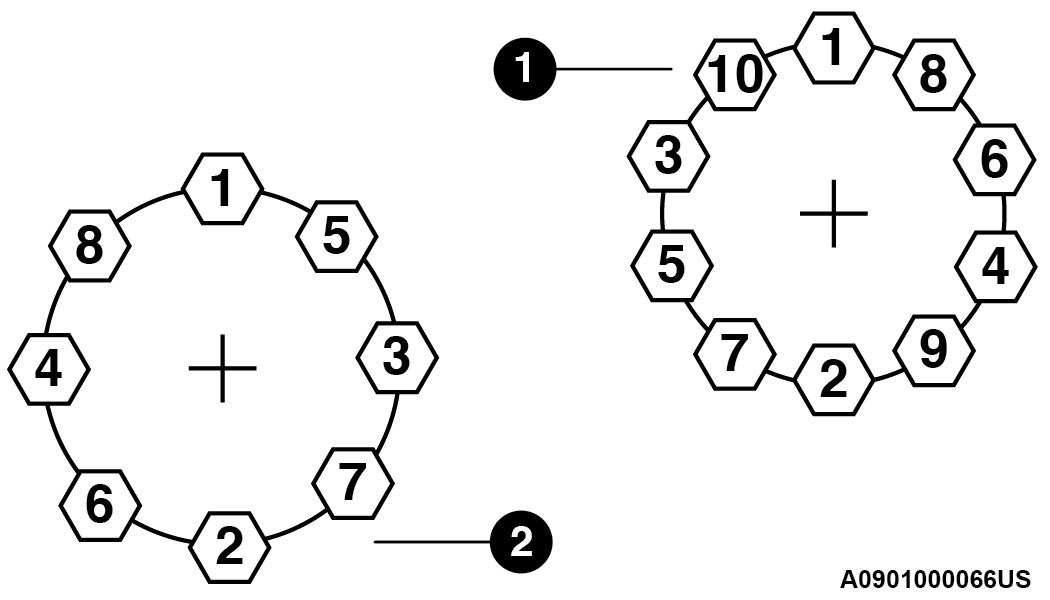

Retighten the wheel nuts, in the same pattern, to the torques listed in the Torque Specifications table. Go through the sequence a second time to verify that the specific torque has been achieved. Retighten to specifications after 25 miles (40 km) and check the lug nut/bolt torque to be sure that all the lug nuts/bolts are properly tightened.

8/10 Lug Nuts/Bolts Torque Patterns

| 1 — 10 Bolt Pattern |

| 2 — 8 Bolt Pattern |

It is recommended that wheel stud nuts be kept torqued to specifications at all times. Torque wheel stud nuts to specifications at each lubrication interval.

All wheel nuts should be tightened occasionally to eliminate the possibility of wheel studs being sheared or the bolt holes in the wheels becoming elongated. This is especially important during the first few hundred miles/kilometers of operation to allow the wheel nuts to become properly set. All wheel nuts should first be firmly seated against the wheel. The wheel nuts should then be tightened to recommended torque. Tighten the wheel nuts to final torque in increments. Progress around the bolt circle, tightening the wheel nut opposite to the wheel nut just previously tightened until final torque is achieved.

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts/bolts fully until the vehicle has been lowered. Failure to follow this warning may result in personal injury.